Installation instruction

Follow the simple steps below

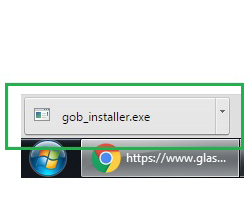

Step 1. Launch the GOB Installer

- Click on the downloaded gob_installer.exe file

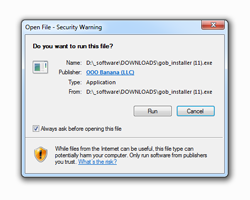

Step 2. Start installation

- Click "Run" in the Security Warning window

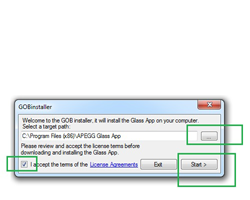

Step 3. Install the App

- Accept the terms of the License Agreement then click the "Start" button

Glass App page

Glass Container - Gob Forming Simulator

Desktop application

The Application requires you to select one of the plans