33 services

Most popular today

- Newly published

- Most popular

- Most popular today

GLASS MODEL

Glass Model has been specialising in the manufacture of hollow glass prototypes since 2003. We make mock up in plexiglass and 3D print since 2006 too.

As the current market leaders in prototypes for the beer, wine and spirits industry. We work with ...

APEGG - Glass Experts

NNPB forming process

The five-step programme from APEGG will ensure a smooth introduction of the Narrow Neck Press & Blow (NNPB) process within any glass plant operation. Following the APEGG way the customer can expect to produce successfully bottle...

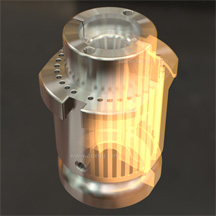

Droigk Formen Service GmbH

MOULDS ARE OUR PASSION - this is why glass factories from all over Europe have trusted DROIGK Formen Service GmbH in the repair of moulds and mould equipment. Always offering our customers the right solution for their moulds - that is our philosophy....

Glass Container Manufacturing Consulting Ltd

We host the Largest Group of Independent Glass Container Manufacturing Experts and Consultants in the World

Together, this represents THOUSANDS of Years of Experience... and all Now Available for You to tap into, with any single request you prese...

DECO GLAS GmbH

Labelling is the application of self-adhesive labels directly to the raw glass or the previously coated bottle. This provides the product with an individual identity as well as an impressive look. Labelling is a successful and economically viable opt...

DECO GLAS GmbH

When colour meets glass and both unite, a simple and in itself unimpressive bottle turns into a real brand packaging. From that moment on, bottle and message are inseparable. DECO GLAS realises your idea, using modern screen-printing technology – whe...

DECO GLAS GmbH

DECO GLAS has been using the powder coating process for 50 years. As a customer, you can benefit from our experience and from our latest developments. For the coating specialists at DECO GLAS are at the forefront when it comes to attractive and funct...

CelSian Glass Experts

LAB EXPERIMENTS AND GLASS QUALITY.

Our glass experts have developed several unique set-ups to study raw materials, refractory materials and physical properties of glass.

Melt observation and Evolved Gas Analysis (EGA)

Video recording of glass fo...

APEGG - Glass Experts

The correct bottle design is as important as the product you fill into the bottle. Brand recognition comes before smelling or tasting the beverage. Understanding all the different hollow glass forming processes and equipment limitations allows our te...

APEGG - Glass Experts

Mould equipment inspection with gauges is very important to ensure a good glass container production. No matter if it is the Neck Ring, Blow Mould, Blank, Baffle, Blow Head, Guide Plate, Plunger (Plug), Thimble or Take Out Tong, all must be inspected...

VPInstruments

Maintain the high-quality standard of your instruments and have confidence in their measurement accuracy with the VPInstruments service programs. Make sure that the cornerstone of your daily decisions is in excellent shape.

VPInstruments service ...

DECO GLAS GmbH

DECO Glitter Coat – A brilliant & inspiring look

Whether sophisticated and elegant or shrill and crazy – Glitter Coat gives your product a completely new character that immediately catches the end customer’s eye. Festive occasions, special editions ...

SPIE EXCELSIUS Global Services GmbH

REGENERATOR CLEANING

INCREASED EFFICIENCY OF YOUR REGENERATORS

When your regenerators are underperforming it is usually caused by sulphates blocking your checkerwork.

We can install our high velocity burner units below the rider arches of your ...

SPIE EXCELSIUS Global Services GmbH

YOUR FURNACE EMPTIED SAFELY WITH REDUCED WATER USAGE

When you need to empty the glass out of your furnace, we can offer you our services for Glass Furnace Tap and Drain.

We work with you to plan a best location to make the hole for your Glass furna...

Service provider

Sector

Service type